Martensitic vs Austenitic Steel What's the Difference

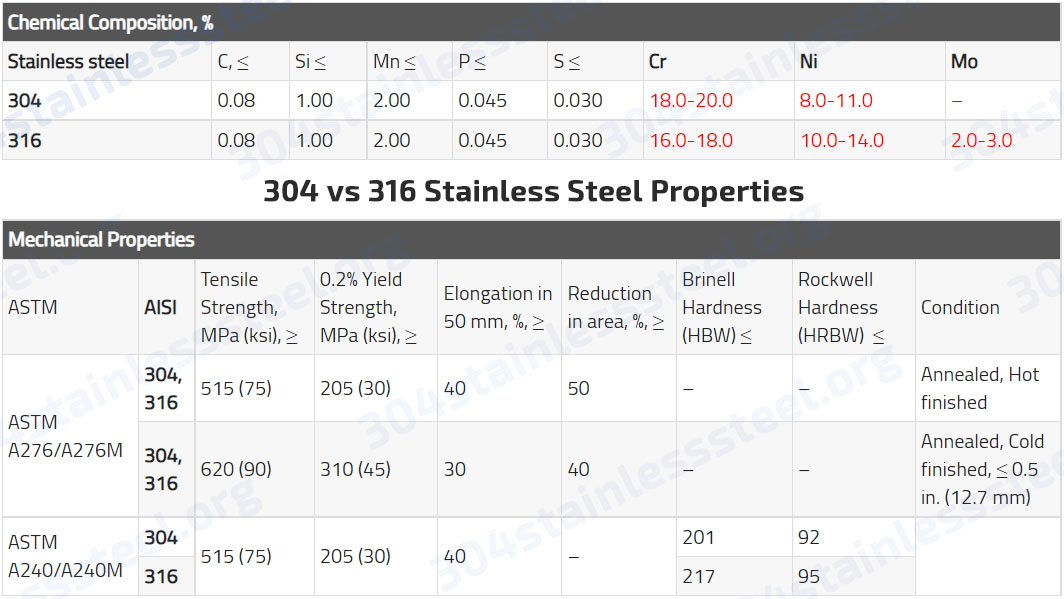

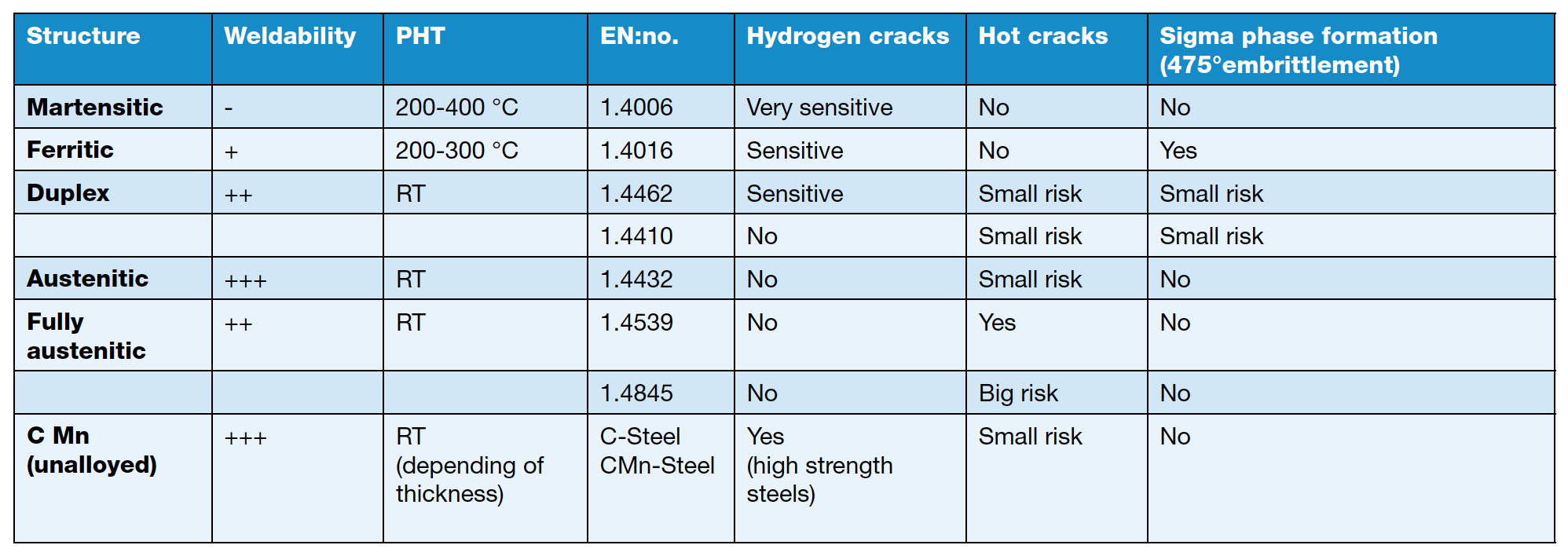

Therefore, in general, austenitic stainless steels have a relatively modest strength, but good impact properties, are easier to form and weld, are non-magnetic and have a range of good to excellent corrosion resistance. By comparison, martensitic stainless steels tend to have very high strengths, lower impact properties, are more difficult to.

Stainless Steel Types of Stainless Steel stainless steel basic concepts applicationmetal

Tweezers made of 410 martensitic stainless steel. Martensitic stainless steel is a type of stainless steel alloy that has a martensite crystal structure. It can be hardened and tempered through aging and heat treatment. The other main types of stainless steel are austenitic, ferritic, duplex, and precipitation hardened.

Class I Martensitic Stainless Steels Hobart Brothers

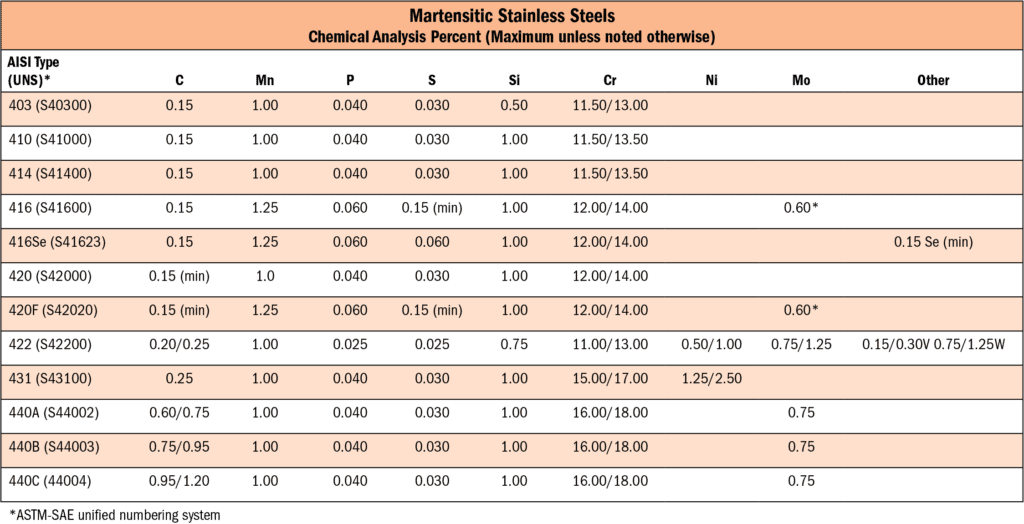

Class I - Martensitic Stainless Steels. The martensitic class of stainless steels shown in Figure 7 depend primarily on Cr from 11.5 to 18% as the major alloying element. This class and the ferritic stainless steel class share the AISI 400 numbering series. They are sometimes referred to as straight chromium grades.

Applications of Martensitic Stainless Steel 1.4057 QT800

Martensitic Stainless Steels Introduction. Stainless steel is the name given to a family of corrosion and heat resistant steels containing a minimum of 10.5% chromium. Just as there is a range of structural and engineering carbon steels meeting different requirements of strength, weldability and toughness, so there is a wide range of stainless.

What is Martensitic Stainless Steel Alloy ? NJXS

All stainless steels are iron-based alloys containing at least 10.5% chromium. The rest of the makeup is defined by various alloying elements, which control the microstructure of the alloy. For martensitic stainless steels, that make up includes carbon and iron. Characteristics: Moderate levels of corrosion resistance, high hardenability and.

Class I Martensitic Stainless Steels Hobart Brothers

Martensitic Stainless Steel Processing Rapid Cooling Martensitic Grades. The most common types of martensitic stainless strip grades are 410 Stainless Steel, 420 Stainless Steel, and 440A. These martensitic stainless steels react to heat treatment much like high carbon steel alloys. The maximum quenched hardness depends primarily on the carbon.

Difference Between 304 vs 316 Stainless Steel

Austenitic steel is a type of steel that contains between 0.8 and 1.2% carbon. This type of steel is soft and ductile and is easy to weld. Martensitic steel is heat treated to achieve its desired properties, while austenitic steel does not require heat treatment. Martensitic steel is typically used for applications that require high hardness.

Types and properties of stainless steels Elga

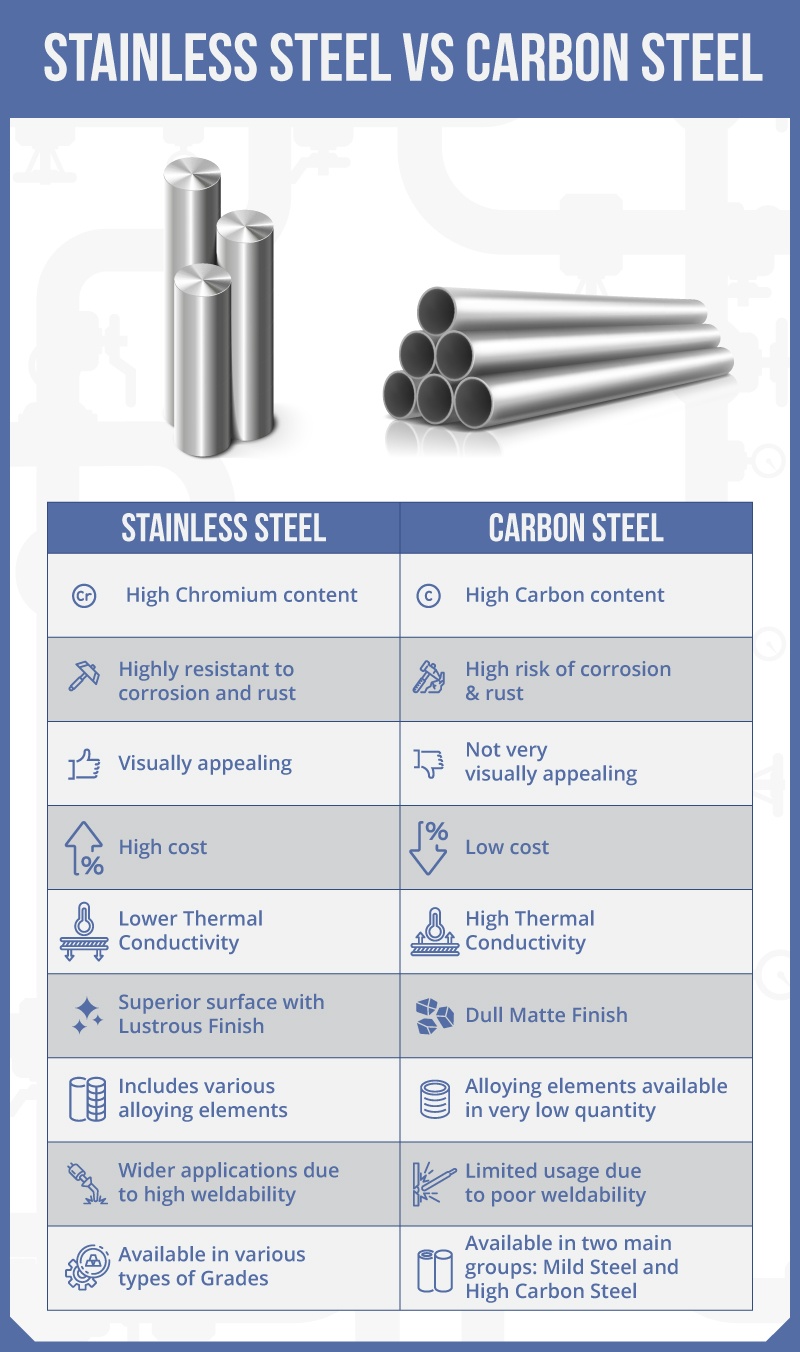

The primary distinction between stainless steel and carbon steel lies in their composition. Stainless steel is an alloy comprising iron, chromium, and other elements such as nickel and molybdenum, which provide excellent corrosion resistance. On the other hand, carbon steel contains iron and a higher carbon content, making it more vulnerable to.

Stainless Steel vs Carbon Steel Aamor Inox

As we know, austenitic stainless steel has no magnetism and good corrosion resistance, such as 303304 and 316202 mentioned just now. Martensitic stainless steel has magnetism, but its corrosion resistance is not as good as austenite, such as 420, 440, 410, 403. So the question is, what is austenitic stainless steel?

Ferritic vs. Martensitic vs. Austenitic All America Threaded Products

Martensitic Stainless Steel. Martensitic stainless steel is known for its strength, durability, and corrosion resistance. At high temperatures it has an FCC structure of austenite that when quenched and tempered can form martensite with a BCC structure. This martensite is a crystalline structure of very hard iron with varying properties.

Martensitic Stainless Steel Grades Knight Group

Its composition allows it to harden and strengthen through heating and aging. Like other stainless steels, martensitic stainless steel is made up mostly of iron with the addition of carbon and other alloys. Carbon makes up around 1.2% of martensitic stainless steel. The other alloying elements are chromium (between 11.5-18%) and nickel.

Is the 316 Stainless Steel Austenitic or Martensitic?

Carbon steel is essentially an alloy of iron and carbon, with small amounts of other elements such as manganese, silicon, and copper. Stainless steel is a steel alloy with at least 10.5% chromium content by mass. It may also contain other elements, such as nickel, molybdenum, and nitrogen, depending on the grade.

Stainless Steel vs. Carbon Steel What’s the Difference?

Martensitic Steel Properties - Why select this material. Magnetic. Hardenable. Hardness range: 170 to 287 BHN annealed; 300 to 625 BHN hardened. Weldable but generally require preheating and heat treatment after welding. Corrosion resistance fair to good and best when fully hardened.

What is Martensitic Steel?

Martensitic stainless steel is a type of stainless steel that contains at least 12% chromium and up to 14% nickel. The addition of molybdenum increases its corrosion resistance. It is martensitic, meaning it can be hardened and tempered. It has a high carbon content which makes it magnetic. The four main grades of martensitic stainless steel.

Buy Martensitic Stainless Steel + Great Price With Guaranteed Quality Arad Branding

Modified grades of 52100 (i.e., ASTM A485-1 and ASTM 485-3) provide greater hardenability. They can achieve a fully hardened martensitic microstructure in thicker cross sections/larger parts. Stainless Grades. 440C - Widely used for its high hardness, 440C is a stainless steel with moderate corrosion resistance properties.

304 vs 316 Stainless Steel Screws Strength & Cost SFS USA

Martensitic Stainless Steel Grades. Grades 410, 420, 431, and 440 are all martensitic grades. This means that they are composed of approximately 12-13% chromium, and iron as the primary alloying element. Learning each grade can help you better understand the properties of this material. You can also select the most suitable grade for your.