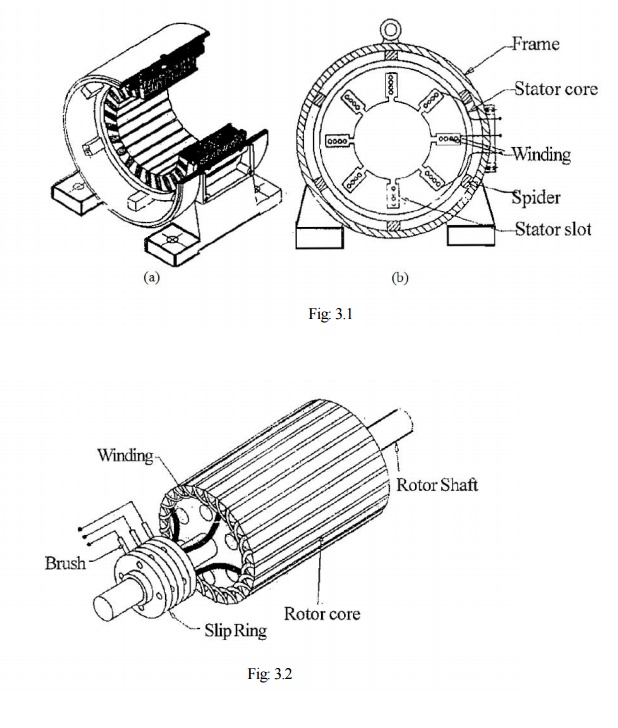

Types and Construction of Three Phase Induction Motor

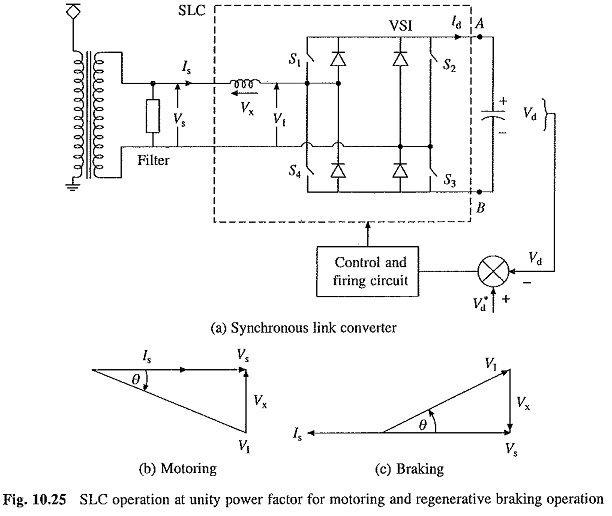

This article will examine squirrel-cage induction motors, wound-rotor induction motors, and synchronous motors in more detail. Image used courtesy of Adobe Stock . Squirrel-Cage Induction Motors. The most widely used motor in industry is the three-phase squirrel-cage induction motor. The squirrel-cage motor in Figure 1 has two parts: the rotor.

Ratings of threephase squirrel cage induction motor Download Scientific Diagram

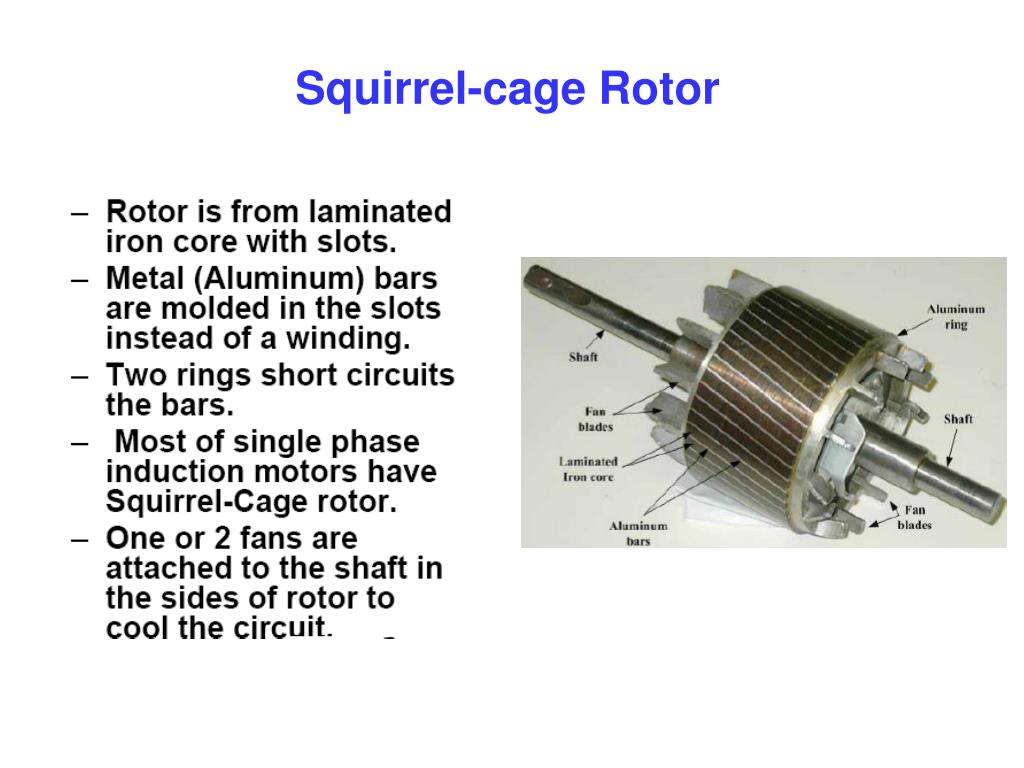

The below diagram shows squirrel cage induction rotor having aluminum bars short circuit by aluminum end rings. It consists of a laminated cylindrical core having parallel slots on its outer periphery.. Most of 3-phase induction motors use squirrel cage rotor as it has a remarkably simple and robust construction enabling it to operate in the.

3 Phase Squirrel Cage Induction Motor Circuit Diagram

The stator and the rotor are the two fundamental parts of any induction motor, and the squirrel cage is simply one method of leveraging the electromagnetic induction effect. The AC current passed through the stator creates an EMF that fluctuates with the AC frequency, which "rotates" around the rotor, inducing opposing magnetic fields in.

3 Phase Squirrel Cage Induction Motor Working Principle

This manual contains information regarding low and high-voltage, three-phase induction motors. Motors with special features can be supplied with specific documents (drawings, connection diagram, characteristic curves etc.). Those documents, together with this manual, must be thoroughly evaluated before proceeding with the installation,

3phase squirrel cage induction motors up to 13,800 V

Other Parts of The Motor. Below are listed other critical parts of the three-phase squirrel cage induction motor: 4 - End Shields. 5 - Fan for cooling motor. 6 - Fan Cover. 9 - Terminal Box. This houses the electrical terminals of the motor. 10 - Motor terminals.

Construction of 3phase induction motor

The series 1LA8 motors are totally enclosed fan-cooled three-phase squirrel cage motors with an internal air-cooling circuit for cooling. Located at the non-drive end of the stator housing is an air intake cowl that guides the external air. The external air is drawn in through an opening in the air intake cowl and flows axially across the outer.

Squirrel Cage Induction Motor Circuit Diagram Wiring Digital and Schematic

Download scientific diagram | Parts of Squirrel Cage Induction Motor from publication: Three-phase Induction Motor: Types and Structure | The popularity of 3 phase induction motors on board ships.

Squirrel cage induction motor Formules de physique, Électrotechnique, Sciences physiques

It's named "Squirrel Cage" due to the unique construction of its rotor that resembles a squirrel cage. The simplicity of its design, coupled with its high durability and low maintenance requirements, makes it an attractive choice for many. The Basic Structure. A Squirrel Cage Induction Motor consists of two main parts: the stator and the.

Squirrel Cage Induction Motor Connection Diagram Pdf » Wiring Digital And Schematic

direction of rotation of the motor rotor is changed by reversing the phase rotation in the motor stator. The motor is force-ventilated by a blower assembly that meets IP44 in the rig installation. 1.2.2 TGA model The WEG TGA Top Drilling Model is a form-wound squirrel-cage inverter-rated AC induction motor designed and

Construction of three phase squirrel cage induction motor YouTube

The overall working of Squirrel Cage Induction Motor is based on the principle of electromagnetism. As the 3 phase supply is given to the stator winding , a rotating magnetic field is produced and the speed is called the synchronous speed. Then the voltage is induced in the rotor bars and causes current to flow through it that creates a.

Induction Motor Inst Tools

5, there are two-phase induction motor and three-phase induction motor. 6, three-phase induction motor power U (200V 50 / 60Hz), T (220V 50 / 60Hz), S (380-440V 50 / 60Hz) and so on. 7. The rotor in the induction motor is not energized. A 3 phase AC induction motor photoed by Hordu Motor. Advantages of three phase squirrel cage Induction Motor

Squirrel Cage Induction Motor Animation Inst Tools

It may be noted clearly at this stage, that the power factor of the induction motor is very low at no load, hardly 0.1 to 0.25 lagging. Efficiency: Full load efficiency of 3 phase induction motor lies in the range of 72 % (for small motors) to 82 % (for very large motors). Speed: When the induction motor is on NO-LOAD speed is slightly below.

Cut Section of 3 phase squirrel cage Induction Motor YouTube

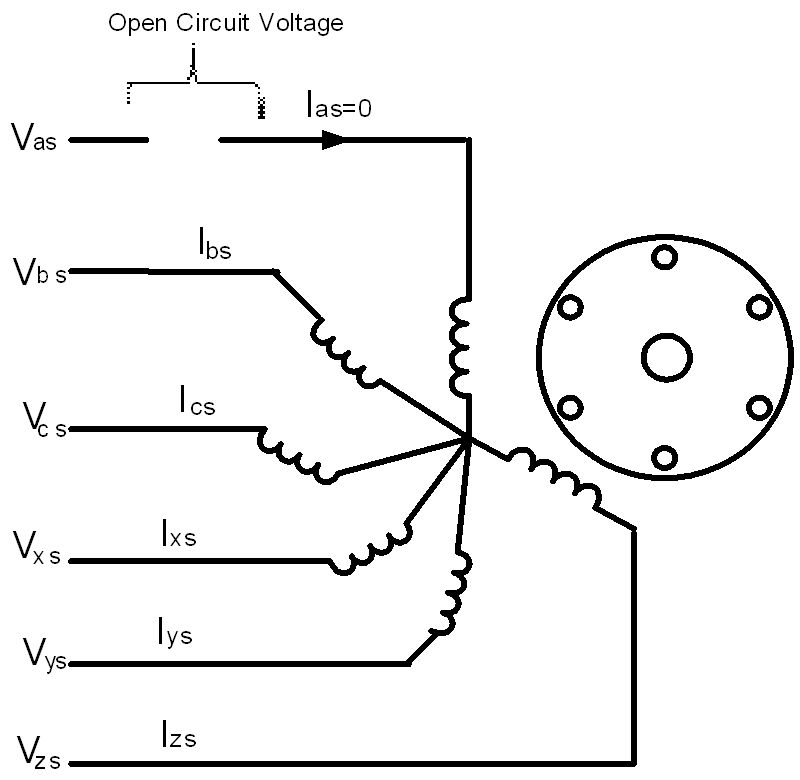

the output. It also has two 3-phase diode bridges for producing the DC output. Induction Motor: This is a small industrial ¼ HP Squirrel-Cage Induction Motor which you have to parameterize. The Stator winding is assumed to be Y-connected with the access to the phase terminals. This motor should be mounted on the Motor Bench, wherein the motor

Diagram of a squirrelcage induction motor. Download Scientific Diagram

Conveyors are driven by 415 V three-phase 50 Hz squirrel-cage induction motors through fluid couplings to protect conveyors during start-up. The motors are totally-enclosed, fan cooled with protection to IP55. Each conveyor is equipped with an emergency trip-wire system running the full length of the conveyor alongside the access way.

PPT Chapter 4. Threephase Induction Machines PowerPoint Presentation ID5653606

3-PHASE SQUIRREL-CAGE INDUCTION MOTOR INSTRUCTION MANUAL MODEL JR-SERIES, HR-SERIES Notice Make sure that this Instruction Manual is delivered to the end user of this motor.. final diagram. (Refer to page 2.) • When coupling the motor with machine, take care to the centering, belt tension and pulley parallelism, etc. When directly

Squirrel Cage Induction Motor Circuit Diagram Wiring Digital and Schematic

Three-phase induction motor designs include: Squirrel cage induction motors - chosen for their longevity and low maintenance. This induction motor design is the most common. Slip ring induction motors - provide a high torque and low starting current; used for e.g. elevators, cranes, and hoists. While induction motors exist in numerous forms.

- Ds B M Van Den Bosch

- Madame Web Release Date Nederland

- Blote Billetjes In Het Gras

- Fiets En Wandelpaden Duursche Waarden

- Ms Oasis Of The Seas

- Humberto Zet Gast Uit Studio

- Racoon Wie Is De Echte Vent

- Wat Is Persoonsvorm In Een Zin

- Schaken Voor Beginners Tegen De Computer

- Amsta De Werf Van Reigersbergenstraat Amsterdam